At a Glance

Services

Data Hub Implementation

PIM Integration

Data Model Development

Architecture Design

Tech Consulting

Industry

Mobility; Premium bicycle manufacturer specializing in e-bikes and cargo bikes

With Data Hub and PIM, we've completely modernized our data landscape and made it more efficient from the ground up. Turbine Kreuzberg was the right partner for this – technologically strong, quality-focused, and always collaborative.

Riese & Müller is growing internationally, offering an increasingly diverse product range and expanding digital services around the connected e-bike. This puts new demands on the premium bicycle manufacturer's established IT architecture. Before the collaboration, the system landscape is still tightly coupled: commerce systems for B2B and B2C are directly connected to the ERP, causing deadlocks and export bottlenecks while severely limiting the renewal.

Objective

Our goal is to bring new flexibility and creative freedom to Riese & Müller's IT landscape. This establishes the technological foundation for international scaling as well as the expansion of new business models like bicycle leasing or subscriptions. The tasks are clear: modularize the system landscape and establish clear responsibilities, optimize data flows, and standardize product data management. We're doing this through two central project streams:

❶ Data Hub — Target Architecture & Implementation:

We're developing a customized data hub at the center of the system landscape that consolidates data and distributes it in a standardized way. It acts as an enabler for Riese & Müller's digital renewal and lays the foundation for future integration of new systems.

❷ Product Information Management (PIM) — Discovery & Integration:

We're handling the preparation and implementation of a new PIM system for cross-system enrichment of product data, relieving the ERP system, improving data quality, and increasing maintenance efficiency.

Solution: Data Hub as the Driver of Digital Renewal

First, we're developing a data hub as the central data exchange point: it receives ERP data, stores it temporarily, and distributes it in a controlled manner to target systems. Specifically, it processes changes in ERP records, converts them into a domain-oriented, R&M-specific product data model, and distributes product data to surrounding systems in a standardized way. These include the ERP as the source system, the commerce systems for B2C and B2B, as well as the R&M website. The hub is also connected to the in-house RX Cloud along with the RX Connect App for the connected e-bike and digital services. Additionally, there are data standards and industry platforms like DST and VeloConnect, through which manufacturers and suppliers centrally provide standardized product data that retailers can access. The landscape is rounded out by a Product Information Management system (PIM) and Business Intelligence (BI).

"With the data hub, we focused on architecture as a strategic decision, not just integration," explains Alexander Janthur, Founder & CEO of Turbine Kreuzberg. "We're bringing flexibility to the system landscape so that Riese & Müller can quickly launch new business models and services tomorrow on an optimal foundation – without constantly starting from scratch."

The implementation was deliberately risk-minimizing and architecture-driven. First, we modeled domains and events and derived clear data contracts from them. We developed the hub itself as a TypeScript-based, event-driven application with Change Data Capture (CDC). This means we continuously capture actual data changes and forward them to the data hub, rather than transferring the complete data inventory each time.

We developed a standardized product data model that consistently represents variants and attributes and reliably delivers enriched information to all channels. To keep shops and channels running as before, existing IDs and data formats are preserved. When data comes from multiple sources, the hub decides which source is responsible for which field and prevents mutual overwrites. New systems are connected gradually while ongoing operations remain stable. This minimizes modifications, increases data quality (clear model, data governance, workflows), and secures operations. In short: a pragmatic decoupling with immediate effect and room for further development. Strong evidence of the data hub concept's viability: Riese & Müller is now applying the architecture principles to an internally developed application for production.

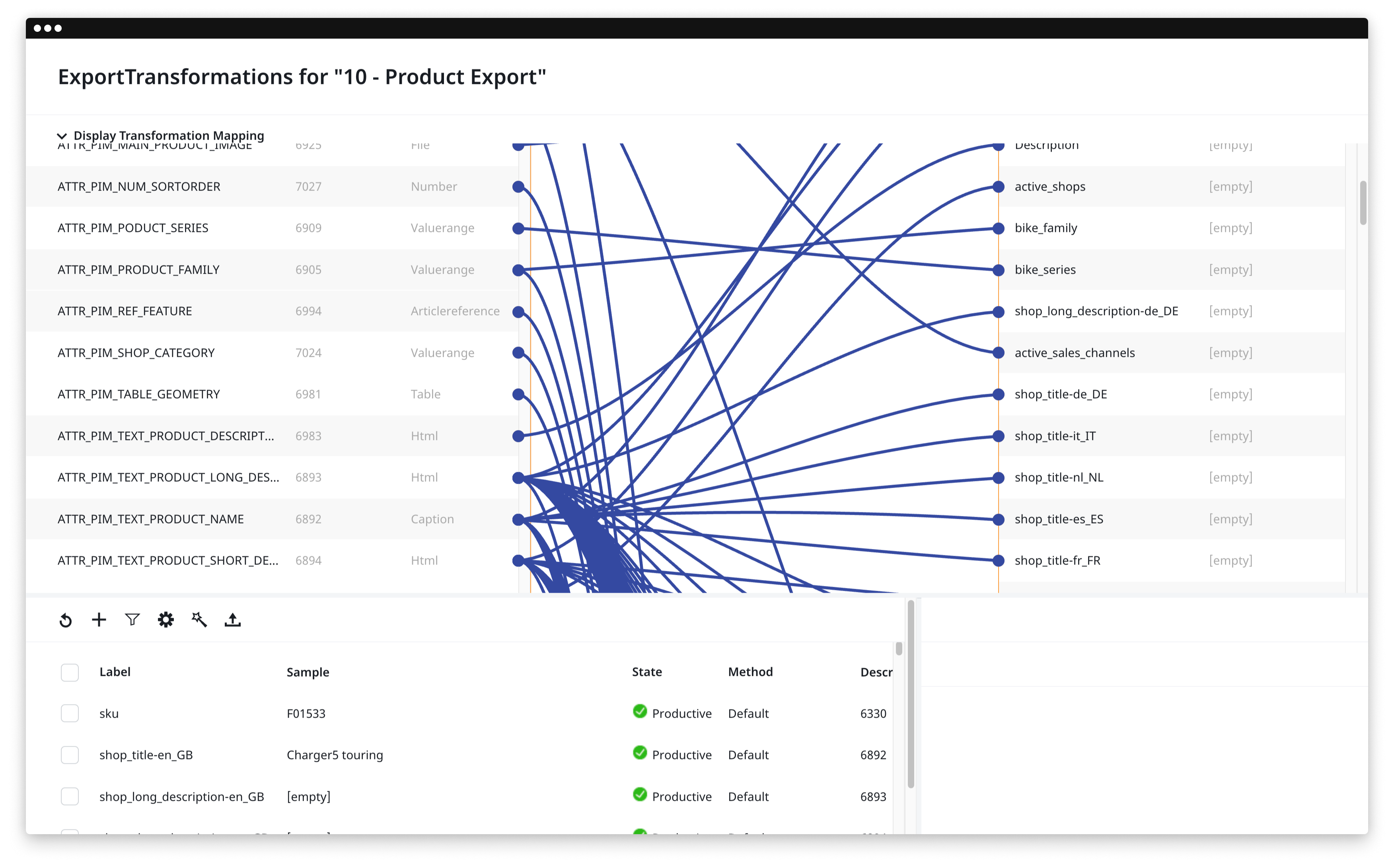

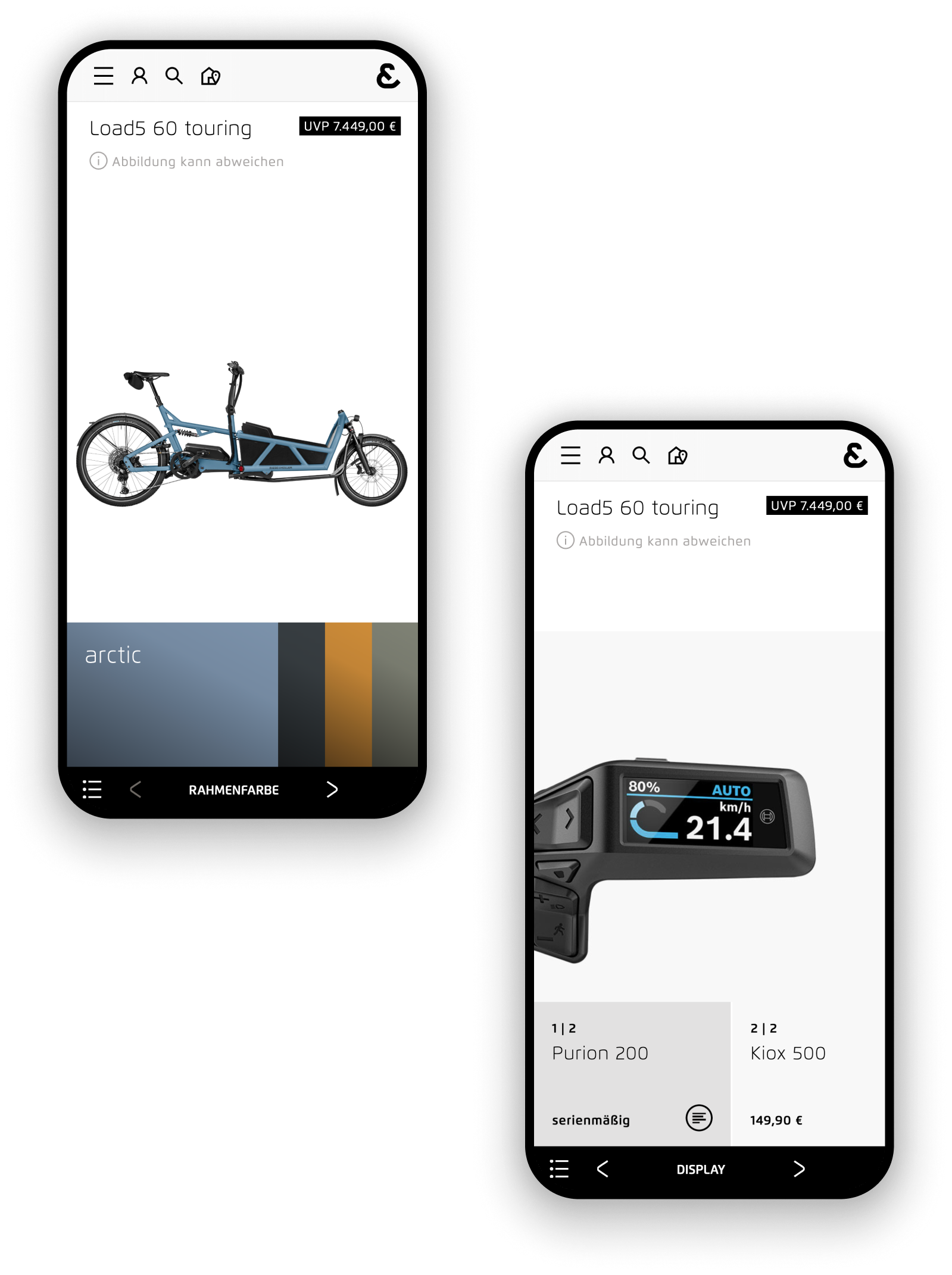

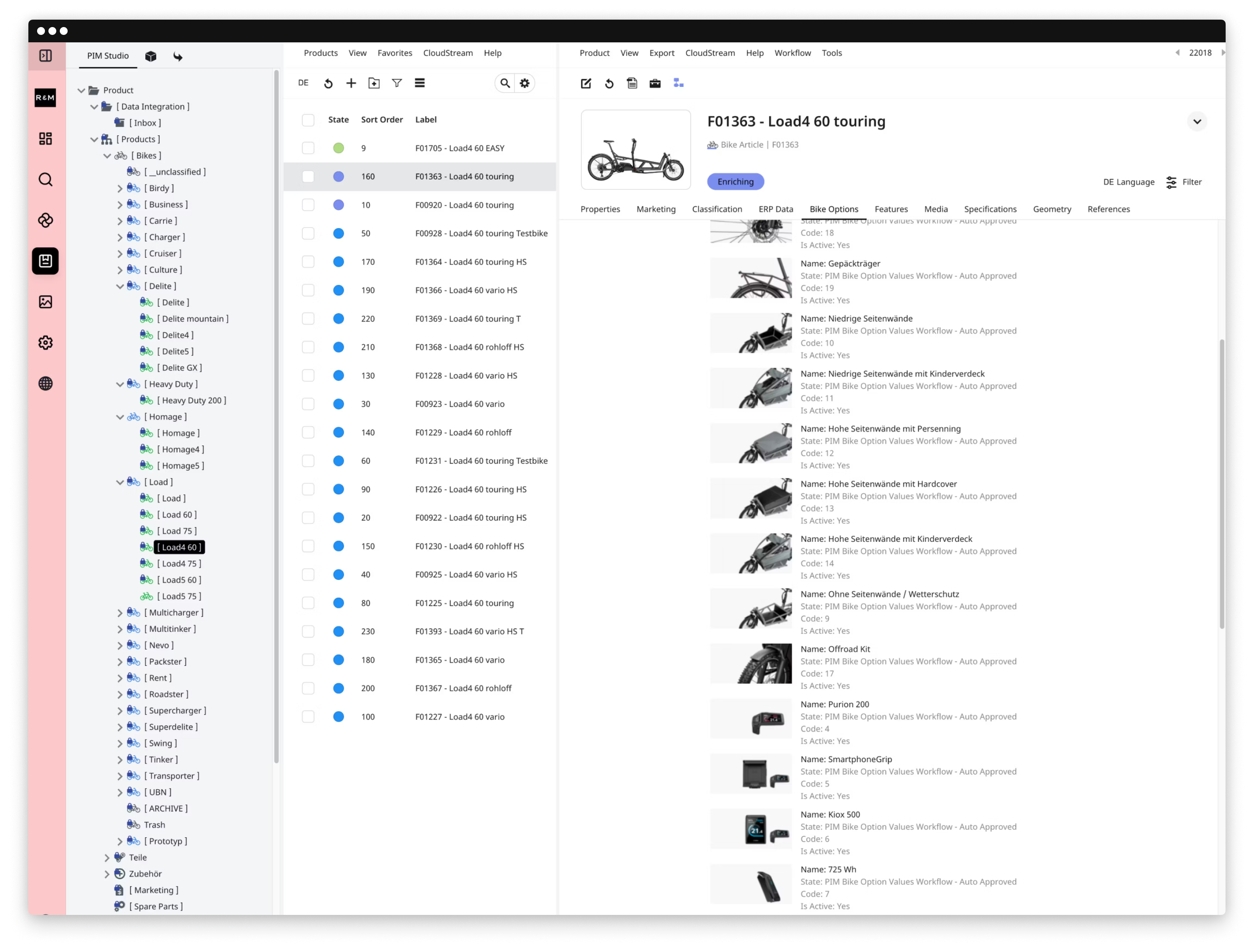

High Data Quality with PIM

With the integration of a new PIM system, Riese & Müller has a central, reliable source for product master data: attributes, variants, relations, as well as country, channel, and translation logic are maintained uniformly, versioned, and quality-assured through workflows. The object-oriented data model with inheritance represents common components across the entire product range, while still allowing enough flexibility for bike-specific texts/images and optional dependencies. Through data contracts, we define how the systems share, validate, and synchronize data with each other, so that the prepared product data reaches all channels consistently via the data hub – without modifications to the connected systems.

The selection of Centric PXM (formerly Contentserv) as the PIM technology was the result of an extensive discovery process. This included expert interviews, process, data, and requirements analyses, as well as the development of target data and governance models (roles, workflows, validations). Centric PXM stood out due to its flexibility, functional breadth (data quality, translation, extensibility), and stable cloud infrastructure.

Products are created exclusively in the ERP and receive their core attributes there. These include core product data such as production-relevant information, configuration data, characteristics and variants, blueprints/bills of materials, serial number products, prices, and inventory.

The data hub receives the "skeleton" of a product from the ERP, composed of the mentioned ERP data, and transforms it into the R&M data model. Configurable products and their variants are linked with the corresponding products from the bill of materials. The hub then sends the product data via push to the PIM, which enriches the data. This includes additional descriptive or metric attributes, linking with objects (e.g., manufacturer, color), adding images, documents, translations, and categorizations, as well as assignment to sales channels including publication and deactivation of products. The hub then retrieves the enriched PIM data via pull and also transforms it into the R&M data model.

Finally, the hub sends the refined product to the commerce systems, transforming it into the required target format. This way, the data is available consistently and ready to use across all channels.

✓ Scalability & Technological Flexibility

The new architecture is forward-compatible: instead of many point-to-point connections, gradually connecting new systems to the hub is sufficient. Extensions, such as new sales channels, markets, or system components, become significantly easier and faster. R&M gains noticeably more technological creative freedom.

✓ Higher Quality in Product Data

With Centric PXM as the PIM, product master data is maintained uniformly, versioned, and quality-assured through workflows. Translations as well as channel and country logic are centrally controllable. Consistency increases, while manual effort and maintenance errors decrease. New variants, content, and channel controls can be implemented faster.

✓ More Performance in the IT Landscape

Through decoupling via the data hub and clear, contract-driven data flows, imports/exports run smoothly without export bottlenecks, even during high load peaks like the model year change and large data volumes.

✓ More Efficient Collaboration

Defined data ownership, workflows, and documented processes create transparency and reduce coordination effort between product, sales, IT, and content teams. This increases autonomy in daily operations and the ability to implement changes independently and securely.

✓ Foundation for Data-Driven Decisions

The data consolidated via the data hub is searchable and analyzable through Business Intelligence (BI). This enables teams to independently run analyses, identify trends, and make decisions faster.

Collaboration

In our collaboration with Riese & Müller, we act as an external tech division on equal footing: shared teams, shared backlogs, decisions in workshops, and a shared space at our Berlin location. Instead of just delivering features, we translate the shared vision – a scalable digital backbone for internationalization and digital services – into a prioritized roadmap. This creates a collaborative working mode in which we act as sparring partners, contributing to strategic, organizational, and technological decisions.

"In projects like this, we're more than implementers: we bring in new hypotheses, challenge decisions, and model an architecture that fits the client's vision," explains Alexander Janthur. "This requires partners like Riese & Müller with a strong vision and the trust to walk this path together."

A key focus is on knowledge transfer and enablement: data models, interfaces, and processes are documented and structured so that Riese & Müller can operate them independently and develop them step by step. Teams access consolidated data, make decisions independently, and no longer need to search across multiple systems in parallel. We shape larger changes – such as connecting or replacing additional systems – together. This creates solutions that work today while simultaneously making Riese & Müller capable of acting independently in the long term.

Ready for more?

Let's talk ideas, challenges, needs, and solutions.

- Alexander Janthur

- Managing Director