Breakout 2022

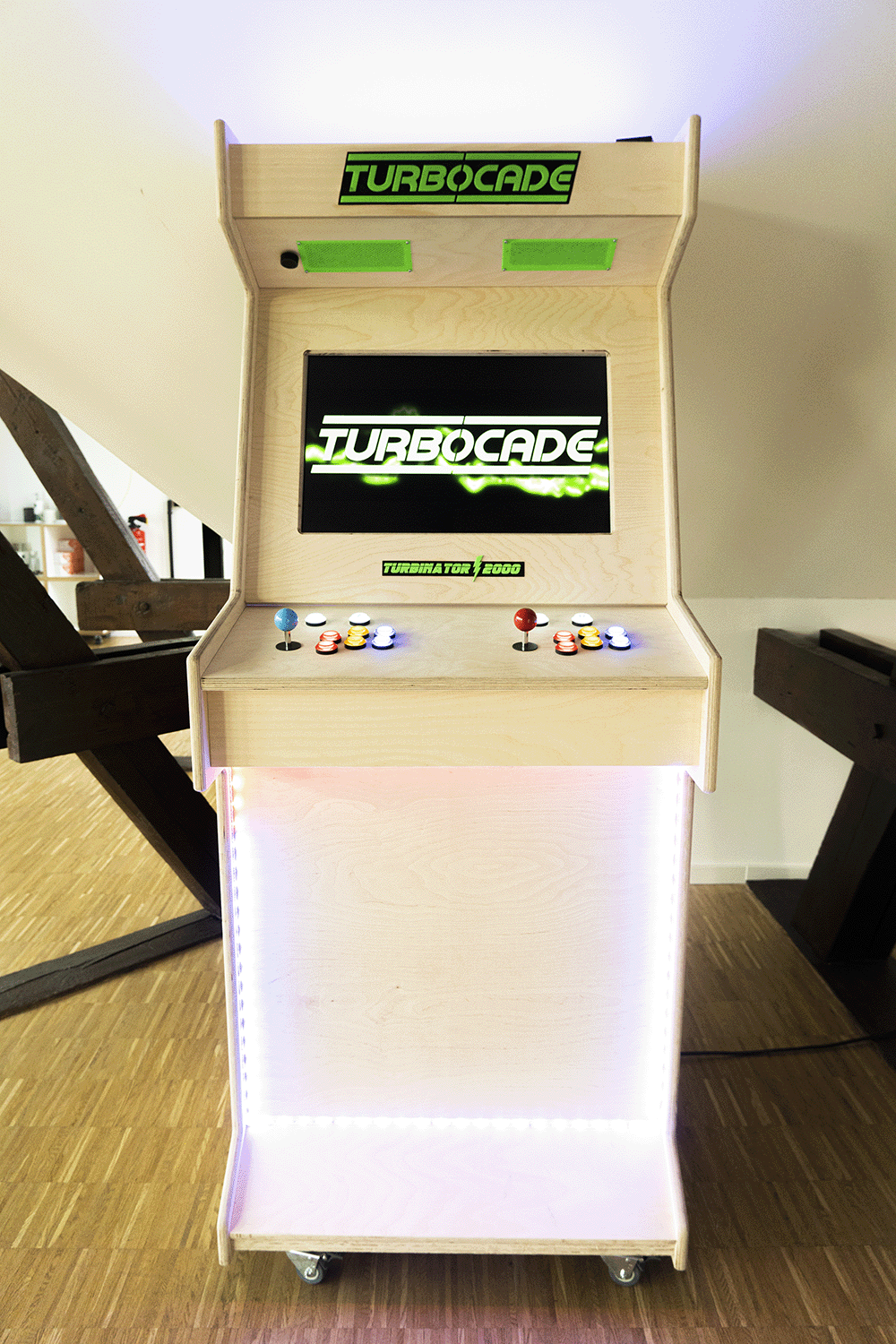

Turbocade Turbinator

2000

A Flashback to the Golden Age of Gaming

November 11, 2022 / Melisa Akbaydar

Each year’s edition of Breakout at Turbine Kreuzberg features a handful of projects that are hardware-focused, with teams building tangible things in the physical, rather than the digital world. It comes as no surprise then that only two days after Senior Developers Marco Morais and João Ximenes announced their own project idea – building the “Turbine Arcade Machine” – more than 20 colleagues had already added their names to the list. “For me, it was the most appealing project during Breakout this year, because it gave me the chance to do something with my hands, instead of sitting in front of a computer. And honestly, I was so scared that I wouldn’t get a spot! It seemed like everyone was interested in joining,” says Thomas Kühnel, Co-CTO at Turbine Kreuzberg.

The project idea was pretty straightforward: building a completely hand-crafted arcade gaming machine using a RaspberryPi 4. While inspired by similar projects found online, the team ultimately decided to make some meaningful design changes to what they had seen before in order to make it more unique. With just five full days’ completion time until the final presentation, and with a construction phase looming that was difficult to fully grasp at first, the project presented challenges across the board. Even so, it was time to get started.

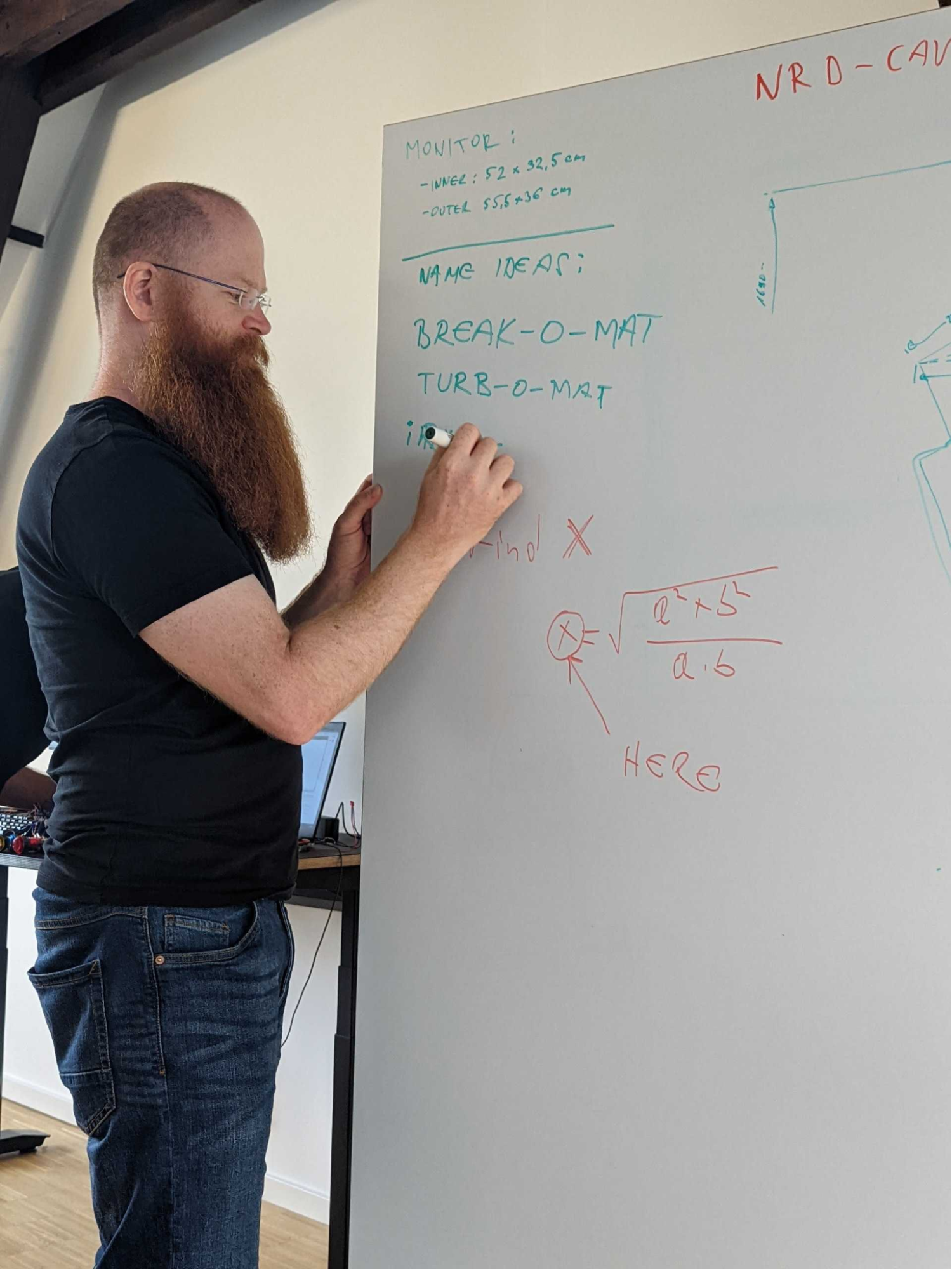

Planning

Since all project team members have a background in tech and software development, they already had a clear idea for the software part of the project. The biggest question mark was how to handle the necessary woodwork. “Luckily we had Thomas,” explains Marco Morais, voicing an opinion shared by the rest of the team. Even though it was his first larger woodwork project as well, everyone was astonished to see his acumen.

Luckily for anyone looking to build things at Turbine Kreuzberg, you can always count on the enthusiasm of founder and CHRO Peter Breuer – who jumped in to provide all the necessary materials, wood sheets and equipment. “The funny part was carrying the huge 70x350 cm plywood sheets to the office from Peter’s basement. It was just a ten minute walk, but they were insanely heavy and we needed three of them,” says Thomas Kühnel.

“Once we had the image of this monumental machine in mind, everyone was like, yes, let's actually build this big thing. Honestly, it was a bit of a quantity over quality situation,” adds Thomas Kühnel. Since the team decided on building something different and much larger than the references found online, making the necessary calculations before cutting the wood sheets was essential. “During the first days, I was a bit concerned that we were not going to be able to deliver the project in five days, because the original idea was so different from the machine that we built,” says Marco Morais.

Besides the unique casing design, almost everything was pre-planned by the project’s initiators. Most of the necessary equipment, such as a DIY arcade kit and raspberryPi 4 8GB microcontroller, were ordered beforehand and ready to use. Some members of the team had already checked how to connect and set everything up. “All the parts were there, so everything came together smoothly,” says Thomas Kühnel. “I even checked a couple of drawings on the internet for design ideas that other people built but on a smaller scale,” adds João Ximenes.

The team also attempted to 3D-model the design before construction, but quickly abandoned the idea due to the lack of time. Rather than that, they decided to print the plan on a wide format printer. In the end, they only printed a test sheet to make sure that the printer was working – and hung it on the wall to feel like there was some ‘engineering’ going on.

Construction

The team split into two working groups. The first step: construction. After all the casing pieces had been cut successfully according to their precise measurements, it was time to fasten the DIY arcade kit and the monitor in place. “We must have measured like 5 times and discussed. But then we just got it on the first try,” says Marco Morais. One question was whether the monitor’s height would work, as all the team had to go on was their visual judgment. “We only held it in the air and 1.70m looked fine, so we drew it on the whiteboard and then directly on the wood,” explained Developer Ruben Manteigas. They stood the wood up and checked it one more time, and then decided to cut it by giving it an ‘L’-shaped curve.

The ‘L’ shaped structure already had support for the monitor placement, so gluing the monitor between the wood pieces after removing the monitor’s base was enough. The speakers needed to be placed inside the casing, but in a reachable way to allow volume adjustment from the outside. For that reason, Senior Developer Flavio Rosa suggested 3D printing speaker grills. As the grills fit on the speakers just right, proving the precise nature of the 3D prints, the team decided to print a logo as well as other features for the machine. “It was very spontaneous, we just kept adding more and more to the overall design,” says Thomas Kühnel.

Having all the parts assembled, the team noticed that the machine was a bit lacking in the color department from the outside. So, just one day before their final presentation, they ordered LED light strips to add to the casing.

Now, what about the name? The time had come for another brainstorming. Out of three options, “Turbocade” was the team’s final choice – with the added model name “Turbinator 2000”, just in case they decided to build more arcade machines in the future.

“Once we had the image of this monumental machine in mind, everyone was like, yes, let's actually build this big thing.”

– Thomas Kühnel

Setting Up the Software

To be able to run arcade games on RaspberryPi, the team decided to rely on the “retroPie” software. The individual games run as ROM files on a USB flash drive formatted to FAT32 (32gb card or under) for maximum compatibility. Part of the team tried to find and arrange all the games that other Turbinies had suggested on the agency Slack channel. “We needed to test the games before uploading just in case some of them didn’t work. When that happened, we needed to remove the faulty games and try different configurations – this was a bit of work,” says Ruben Manteigas.

Developer Ricardo Lucas specially designed a splash screen including logo and animation, and configured retroPie to show it to the player before each game start. “Of course, there was a point when retroPie simply broke down and it didn’t work at all. It was the biggest failure that we faced,” says Ruben Manteigas. Hardware troubles were also a setback, as connecting both controllers proved tricky. Still, problem solving was a fun task, despite being time consuming in a project already pressed for time.

Testing

”Before we built anything, we had a prototype made out of a cardboard box with joysticks, buttons and other controls. We tested the DIY arcade kit components while playing the games and configured the joysticks in order to find out a default layout based on the colors of the buttons – just as how it would have been in a typical arcade machine,” says Ruben Manteigas. They tested all of them step by step to see if each part was working.

“The most ironic part of the project was that we built, gathered, assembled, and tested the machine in the basement, but in the end, we were not able to bring it back upstairs, because it just wouldn’t fit through the door. So, we disassembled the whole machine and put it back together again upstairs. It was like IKEA,” says João Ximenes.

On day five of Breakout 2022, at the end of the all project presentations, the Turbicade team finally unveiled their machine to everyone at Turbine Kreuzberg. When they powered it up, everything worked perfectly, and the team saw their colleagues’ reactions, they were understandably elated.

“For me, it was amazing to see everything working, especially with the LEDs we added at the very end,” says João Ximenes. “When this thing came to life with the lights and everything, it was exactly as monumental as I thought it would be. A big, flashy box, like I had imagined from the very beginning,” adds Thomas Kühnel. “I was excited every morning to keep working on this project.” All team members’ signatures grace the back of the machine, proving just how proud they are of their work.

When asked if they would consider working together again on a similar project in the future, everyone was quick to agree. “We still need one more for the Faro office, after all,” says Ruben Manteigas. “And maybe for the Turbinator 3000, we will paint it and make it more colorful. Or add a bottle holder, who knows?”

Want to try your hand at beating our highscores? The Turbocade Turbinator 2000 resides in Turbine Kreuzberg’s headquarters in Berlin, making for entertaining gaming nights, team lunches, and little breaks in between building really great software.

Melissa Akbaydar

Technical Writer

melisa.akbaydar@turbinekreuzberg.com